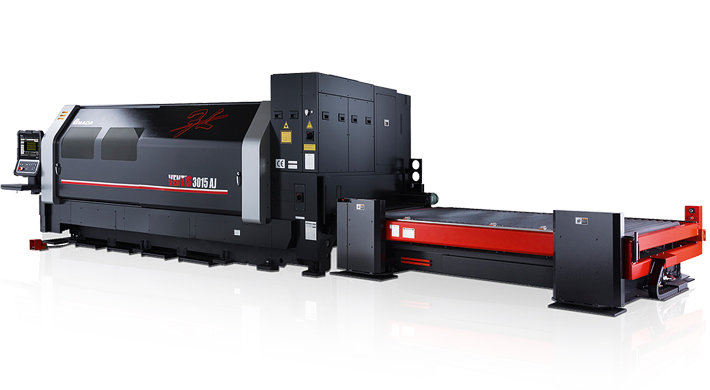

The AMADA VENTIS-3015AJ is the world’s first new-generation fiber laser that shows off its strengths in the machining of stainless steel and aluminum, in particular – fast and with high cutting quality, it is efficient, economical and reliable. The highlight of the system is its unique LBC technology that makes it possible for the beam to move from side to side almost without restriction during the cutting operation.

Since the beginning of the year, a fiber laser cutting system has been available, in the form of the AMADA VENTIS-3015AJ, that for the first time permits the extremely high speed cutting of stainless steel and aluminum, in particular. This is possible, among other things, thanks to the unique, patented AMADA Locus Beam Control (LBC) technology. Using this technology, the laser beam moves from side to side in different movement profiles around a defined cutting point.

Furthermore, without this technology, it would not be possible to choose between the three different operating modes: “Productivity Mode” for maximum cutting speed, “Quality Mode” for practically burr-free cutting as well as “Kerf-Control Mode”. This makes it possible to vary the kerf width during cutting and even increase this value to up to twice the width obtained with conventional solid-state lasers. This ensures that every part can be removed perfectly and reliably during the process, either manually or automatically. At the same time, the LBC technology and the side-to-side movement of the laser beam make it possible to eliminate the slag from the cut quickly and reliably.

More performance, lower costs

In addition, the AMADA VENTIS-3015AJ also excels through its particularly high performance, as numerous practice-oriented comparative tests have shown. Consequently, compared to conventional 4-kW solid-state lasers, it is possible to achieve productivity increases of up to 250 percent, in particular when machining aluminum and stainless steel, while simultaneously reducing operating and manufacturing costs by as much as 70 percent. “As far as productivity and cost efficiency are concerned, the AMADA VENTIS-3015AJ with its four kW is perfectly able to measure up to laser machines in the 6-kW class or even more powerful systems,” stresses Axel Willuhn, Product Manager for Punching and Laser Technology. Another advantage: AMADA naturally also makes the entire cutting data library available for the AMADA VENTIS-3015AJ. This means that the machine can be operated and used without problems just like a conventional laser system. Alongside compatibility with the automation modules of the AMADA fiber laser systems, this was an absolutely vital development criterion. All in all, the AMADA VENTIS-3015AJ is a high-performance machine which, first and foremost, is intended for the fast, efficient, reliable cutting of stainless steel and aluminum. In this way, it is differentiated from the systems in the AMADA ENSIS series, which are designed as all-rounders offering higher power for cutting all material types. “The AMADA VENTIS-3015AJ and the ENSIS systems complement one another and offer individual strengths that bring about specific benefits. In this way, we can ideally cover all customer requirements,” is how Willuhn sums things up.

Images: AMADA GmbH